This site uses cookies.

Mechtex uses cookies to enhance your browsing experience, analyze site traffic, and improve our services. By continuing to use our website, you consent to our use of cookies. To learn more, read our Privacy Policy.

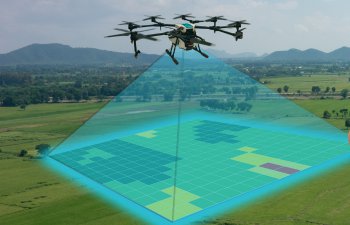

Drone motors are the mechanical components responsible for generating the necessary thrust and propulsion to keep a drone airborne and maneuverable. They convert electrical energy from the drone's battery into mechanical energy, which drives the propellers to produce the necessary lift and control. Mechtex is a well-known drone motor manufacturer with a focus on creating high-quality drone motors. Drones typically use brushless motors due to their efficiency, reliability, and power-to-weight ratio. Drone motors produce thrust by spinning the propellers. The amount of thrust generated depends on various factors, including motor power, propeller size and pitch, voltage supplied to the motor, and overall drone weight. Lightweight, small, and effective, make Mechtex a leading drone motor manufacturer in India. They are a perfect companion for a variety of drone applications. Our drone motors are made with aerospace-grade materials and the most modern design and manufacturing techniques to guarantee that they uphold the highest levels of quality and longevity. Through our commitment to excellence, innovation, and knowledge, Mechtex is a dependable and valued producer of drone motors. Thanks to rigorous testing and quality control procedures, we ensure that our motors work consistently and dependably, even in the most demanding situations.

Offer longer flight times, improved maneuverability, and enhanced aerial performance of Drone

Ensures optimal performance, prevents overheating, and extends motor lifes for reliable and safe flights

Enables precise control, and better stability and Safe Flight and Landing

Provide superior lifting power, enable stable flight and reliable performance in challenging conditions

EL-108, Electronic Zone, Mahape TTC Industrial Estate, Navi Mumbai - 400709, Maharashtra India