This site uses cookies.

Mechtex uses cookies to enhance your browsing experience, analyze site traffic, and improve our services. By continuing to use our website, you consent to our use of cookies. To learn more, read our Privacy Policy.

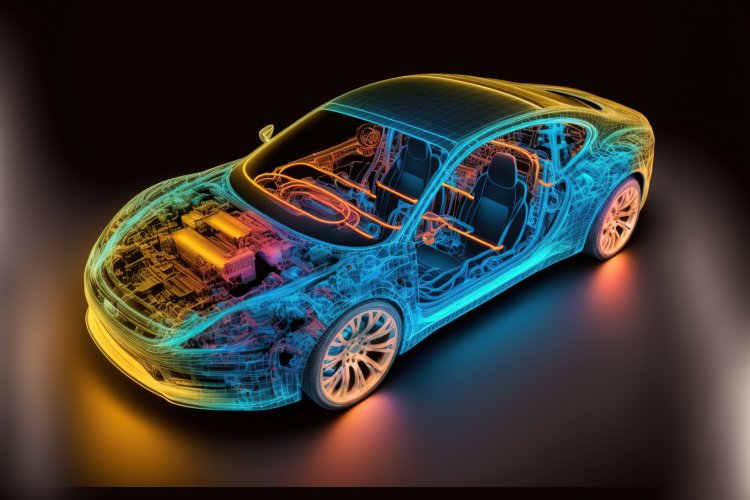

Unlike traditional brushed DC (Brushless DC) motors, BLDC motors do not use brushes for commutation, which eliminates the need for maintenance and reduces friction and wear. It provides higher torque and speed with less energy consumption which results in lower operating costs. BLDC motors are commonly used in various applications, including electric vehicles, drones, industrial machinery, and appliances. There are primarily three types of BLDC motors based on the construction of their rotor: Outrunner Motors, Inrunner Motors, Housed Motors. Mechtex is one of the leading BLDC motor supplier in India. You can have trust in the dependability and performance in our Brushless DC motors thanks to its low maintenance needs and constant technical support from the Mechtex team As a BLDC motor exporter, each motor at Mechtex is subjected to a stringent quality control process to guarantee that it satisfies or surpasses industry standards.Various checks and testing are conducted during the manufacturing process, and the motor must pass a final inspection before being supplied to the customer. Mechtex has become a world leader as a BLDC motor supplier thanks to their dedication to quality, innovation, customisation, experience, and customer service.

Enables faster acceleration, better performance, and increased efficiency.

Enhancing efficiency, stability, and reliability of motor in various applications

Help to operates more effectively and conserve less power to provide the same output performance

Increase Motor Life Span and Ensures uninterrupted performance of motor

EL-108, Electronic Zone, Mahape TTC Industrial Estate, Navi Mumbai - 400709, Maharashtra India